|

Jeff Wood, Urban Milwaukee, July 20 2019 Original article published on Urban Milwaukee. Houston's Massive Mistake'Meet Your Digital Twin: City planners are beginning to utilise 'digital twins', computer-based replicas of physical cities that reflect the dynamics of cities, including the people and vehicles that move through it. The tool is helpful to combat public skepticism toward planning projects, as models of digital twins effectively represent anticipated street conditions based on a variety of parameters. Digital twins can be used to predict future traffic conditions or air quality. This kind of urban modelling does require extensive data collection, including anonymized smartphone data, but some cities are already implementing the technology despite concerns over privacy. Portland, Oregon, is launching a one-year pilot to virtually replicate its city from scratch with the aid of a digital twin (Wyatt Cmar & Stephen Goldsmith / Governing)' Digital twins have been created that can be used as virtual replicas of cities, and that have the ability to predict future conditions that may affect a city through data collection. But while many find privacy a main concern when it comes to digital twin technology being utilised in cities, it does not need to be a worry.

Technology exists today, using digital twins, that keeps privacy and security central, and an important part of the way that they function. The creation of an interoperable ecosystem that stores all the data you own through digital twins of your assets, means that you are able to pick and choose who you share your data with. Therefore, digital twins of cities are able to function to their full potential, predicting conditions such as weather, traffic, and air quality, as well as aiding in construction projects by collecting data that may affect them, while privacy remains in-tact. This technology is available to you, today. Find out more on our website.

0 Comments

Laura Bliss, City Lab, July 19 2019 Original article published on City Lab. The Surprisingly High-Stakes Fight Over A Traffic-Taming 'Digital Twin'This article by Laura Bliss for City Lab, explores thoughts on digitising traffic and the use of digital twin technology to accomplish this. She goes into the pros and cons that coincide with using this kind of technology to control and gain information from vehicles, and discusses different ways to solve the issue of traffic control.

What becomes apparent throughout the article, is the issue of privacy in digital twin technology, and how this might cause people to hold back on utilising it. Privacy, when it comes to you and your data, is hugely important and having to worry about whether your personal data is being used in the right way or not within your everyday life, is not something people want to have to think about. What we really need is a digital twin solution that allows individuals to have control of their own data. That solution is available right now. Using a single ecosystem that allows the data owner to pick and choose who they share data with and what data they share, removes these privacy concerns. This puts the control entirely into the hands of the person or company that the data belongs to, reducing the risk of unwanted data sharing and hacking of personal information, as in the Bradley Cooper case. This means that we can make massive technological advances such as these, without having concerns about people opposing the idea, without worrying about the welfare of the population, and without giving too much power to single companies, organisations, and individuals. This technology also means that hacking is more easily avoided as information only makes sense to the person who is seeking it, therefore if an interception is made, the hacker can only gain that one piece of data which will mean nothing to them without context. This technology could help towards digitising traffic and creating more safe and efficient roads, without the need for privacy concerns and worries about too much control being put in the hands of individual companies and people. Digital twins and their own secure interoperable ecosystem are available and are being used right now. Find out more on our website. Emma Koehn, The Sydney Morning Herald, July 15 2019 Original article published in The Sydney Morning Herald. Tracking Cracks: The start ups aiming to stop apartment disastersEmma Koehn makes some really important points about the future of construction and engineering and about potential solutions to building collapse. But Digital Twins are more than just 'blueprints of businesses'. They have the ability to detect and predict problems on active sites to prevent issues within the building process, as well as to prevent the potential of future collapse. However, there is more that needs to be explored.

Construction sites are busy and often dangerous environments that rely on a multitude of elements in order to function smoothly. An issue with any one of these elements can cease a day's work and even the development of a project altogether. Therefore, it is imperative that companies do everything within their power to prevent these issues. It is also important, as Koehn agrees, that companies can ensure the safety of their buildings in the long run, and reassure customers that there will be no damage or issues into the future. Therefore, technology that is able to predict problems on site at the building process level, as well as technology that can aid the prediction of potential issues into the future after building completion, is entirely necessary in order to prevent future collapse or damage. While technology with the ability to do these things does exist today, many businesses are missing the mark when applying it. The article mentions the use of bluetooth sensors to monitor different parts of construction sites and to alert the company when issues arise, which is a huge and important step in digitising construction and enabling companies a better insight into the functions of different elements of a site. But we can go further. The adoption of multiple apps and technologies like sensors, creates complexity. How can the data we are collecting from the sensors be utilised in a more efficient way? A single app solution that collates all the data from any asset - whether this is an app, an engine, a sensor, or an entire construction site - automatically into one ecosystem, could be the answer. Within this ecosystem the data would be able to comprehensively communicate with other data, and provide the user with one continuous feed of information that is entirely relevant to their needs. Intelligent Digital Twin technology is being used today within the construction and engineering industries, which has the ability to detect faults and problems during the building process, and alert the user to an issue as soon as one is detected. This ensures the smooth running of an active site and prevents current issues and dangers, as well as preventing the future collapse or damage of a building. And it can do more. Digital Twin technology is able to predict issues on an active site, before the issue even occurs, by collating information that may affect an asset from both internal factors - such as information from sensors monitoring the asset - and external factors, for example, wind speed, temperature, and tracking of important deliveries. This information is presented in a continuously updated river of news, providing a single source of truth so a site can determine whether precautions are needed to prevent dangerous situations and damage, as well as to maintain the smooth running of the site. This technology is available and being used as we speak. Discover more about current uses in construction and engineering in our collaboration with BAM Nuttall and Cranfield University via The Learning Camera website. And find out more about how it can help your business today, whether it is construction related or not, on our website. Farai Mazhandu, IoT For All, July 12 2019 Original article published on IoT For All. IoT Applications in ConstructionFarai Mazhandu makes some great points in this article in IoT For All about IoT applications being used in the construction industry to improve different elements of its running.

The need for improvements to everyday tasks and functions on construction sites to make them more efficient and safe working environments is becoming ever-more imperative. However, the future of construction is about more than just IoT applications. It is about how these apps are able to comprehensively cooperate and communicate with one another and how the data they are collecting is able to be shared, as well as how relevant information can be gained more quickly and efficiently. It is about enabling interoperability within a construction site, meaning issues can be flagged more quickly and predictions can be made on site about potential factors that may affect assets, meaning companies are able to determine how to approach the day's work, for example, when certain equipment should not be used or how long a delivery will take. This information can all be presented within one feed, giving the user a single source of truth about any particular asset. Predictions like this can ensure the smooth running of active construction sites, diminishing the fear of work having to cease altogether, and ensuring construction can be completed on time and to the best possible standards. This kind of intelligent technology is available and being used right now, that has the ability to improve safety, security, efficiency, and overall productivity on construction sites, all within one interoperable ecosystem, using Digital Twin technology. We at Iotic are enabling this interoperability today, through Digital Twins, an example of its use in construction being through one of our ongoing collaborations with BAM Nuttall and Cranfield University, which you can learn more about on The Learning Camera website. However, construction isn't the only sector that Digital Twin technology is able to improve. It can help any company, today, find out more on our website. John Williams, World Coal, July 1 2019 Original article published on World Coal. GE Research: Flexible Plants for More Renewable Intensive GridsThis article written by John Williams for World Coal, makes some interesting observations about using Digital Twins to make coal power more sustainable. This is through their predictive technology that allows data sources to interoperate and predict whether a fault might occur, before it has even happened. This is done by creating a Digital Twin of the coal power plant and allowing it to intelligently interact with other twins within a single, interoperable ecosystem. This allows data to be accessed and shared both internally and externally to the power plant, meaning information such as weather and temperature, which may affect the coal power production, is easily accessible through a single feed of information, and can be used to predict whether a fault might occur.

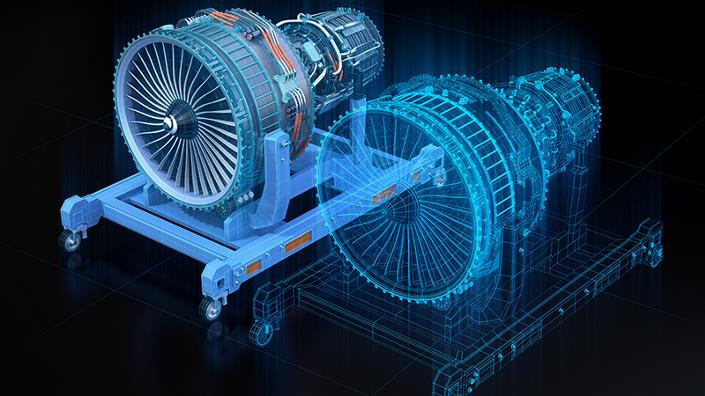

Using this same technology, similarly to our work with BAM Nuttall and Cranfield University with The Learning Camera, you can then monitor elements of the coal power plant, and the intelligent technology will alert you to an issue when one arises. This diminishes the fear of human error and sometimes dangerous environments that checks could be conducted in. Find out more about Digital Twin technology and how it can help to not just make coal power a more sustainable and efficient source of energy, but how it can help any business or company to increase efficiency and overall productivity, on our website. Joseph Chukwube, ReadWrite, June 28 2019 Original article published on ReadWrite. Electronic Design is Utilizing AI-Enabled Solutions to Render Top-Grade ServiceThis article written by Joseph Chukwube for ReadWrite explores AI solutions for the engineering industry, specifically in Electronic Design companies, commenting on customer engagement, how companies are able to communicate between themselves and their machines, and predictive technologies. However, while the majority of the points Chukwube makes are true and align with our values at Iotic, many of them need to be taken further. 1. Harnessing Effective Data Chukwube here, states that 'data, no matter how voluminous, is practically useless when not properly organized and analyzed.' This is true, but how should this be tackled? He touches on the use of Digital Twins and how they can be used to monitor data and predict problems before they arise, but this doesn't reach the full limits of how Digital Twins can be used to help a company's data. Digital Twins do more than just monitor systems to predict issues and analyse data, they have the ability to gather and share information, internally and externally to a business. This allows a user to gain information that is entirely relevant to them and their company, without having to lift a finger, and is how the predictive qualities of Digital Twins are enabled. Twins of individual assets, whether this is a single engine or an entire construction site, can be created, which produce a feed of information about the asset, as well as potential factors that may affect its functioning, such as weather conditions, wind speeds, or delivery information. Digital Twins make this all possible, and more, today. 2. Faster and More Efficient Communication While it is true that technology exists today that can bridge a gap between a business and their machines, predicting issues before they occur, this technology can be - and has been - developed even further. These predictions are based on real life data, and new technology means that this data can be collected and collated all into one place, so information can be gained with ease and with minimal effort from the user. Therefore, this not only gives businesses the ability to communicate with their machines and gain information and data quickly and easily, but also allows them to collate all the information they receive into one single location, giving a single source of truth that is more easily utilised. It also enables a business to communicate with data sources outside of their immediate company, to gain additional information that gives them 'the flexibility to meet up with demands, prevent downtime losses and control cost'. 3. Customer Engagement Agreed, 'customer engagement is crucial' in order to maintain efficiency and stability within a business, and chatbots are a start at improving customer service and ensuring that efficiency and customer satisfaction remain high. But wouldn't it be great if companies were able to more easily and quickly access important and relevant data for their customers? Technology exists and is being utilised today that provides companies with a single source of truth, allowing data and information to be more easily accessed and utilised to solve customer enquiries. Find out more about a real use case of this technology in our collaboration with Rolls Royce Power Systems, and discover how this technology can be useful to you, your business, and your customers. 4. Quality Checks and Control Ensuring that quality checks are conducted to the highest of standards is important to ensure the smooth running of a site, these checks require accuracy and can also sometimes be dangerous, so relying on human checks alone can be risky. Therefore, a practical solution such as a 'high resolution camera' that 'not only views but processes the information gathered such that defects are automatically flagged for correction', could be the answer. Iotic have developed intelligent technology in partnership with BAM Nuttall and Cranfield University, called The Learning Camera, that does exactly this. 5. Implementation of Virtual Assistants Quality checks are an example of a job within a company that is time consuming, sometimes dangerous, and often repetitive. Therefore, if technology exists today to assist with these kinds of tasks, why wouldn't we jump at the chance? Intelligent technology can not only do the odd job that Chukwube describes, but it can help increase efficiency and productivity hugely throughout a company, as it frees up time for individuals to undertake other jobs. This includes tasks like quality and Health & Safety checks, as well as the everyday running of the business, as data is much more easily accessible, quickly and with complete relevance to each specific situation. This technology exists today to increase business efficiency and free people from time consuming and sometimes dangerous tasks. 6. Predictive Maintenance 3D generated models were only the beginning of predictive technologies and how they may help to detect issues with assets and products. Digital Twin technology can provide accurate, real time information that can help companies to predict factors that may influence the development of a project or that may affect a specific asset. A Digital Twin is not a 3D model of something, as many believe it to be, it is instead a virtual copy of a particular asset, whether this is a person, an engine, a car, or an entire building site. This Digital Twin is then able to interoperate with other twins within one ecosystem, gaining information that is entirely relevant to the user's needs, without them having to monitor or continuously programme information into it. A river of news can then be created which provides the user with any piece of information that could want to know about this specific asset, as long as it is relevant to their specific needs. This technology is available right now, and is helping companies to improve in productivity, customer service, cost effectiveness, and overall company efficiency. Conclusion Intelligent technology exists today and can not only help the Engineering Industry, and more specifically Electronic Design companies, but can help any business no matter how large or small. This is in the form of Digital Twins which have the ability to do all of the above, within one interoperable ecosystem, without the need to adopt a multitude of technologies and without creating complexity within your business. They provide answers to all your business problems, quickly, easily and effectively, with minimal effort and time from the user. As Chukwube agrees, you should consider joining the revolution, for fear of missing out on all this technology has to offer you. Discover more on our website.

Jan Rowell, Inside HPC, June 28 2019 Original article published in Inside HPC. Advancing Manufacturing with Simulation Based Digital TwinsThis article, written by Jan Rowell from Scientific Computing World for Inside HPC, eloquently explores simulation focused digital twins and real use cases within the manufacturing industry. The article also looks into ways digital twins can be used outside the manufacturing industry, and for more than just simulation of a physical asset.

Intelligent digital twins are being used today, both to simulate real life assets and predict factors that may affect them, as well as to interoperate with other twins, internally and externally to a business, in order to aid these predictions and discover information that may affect their real world counterparts. These twins are accessible to you, right now. Discover more on our website. Bhaskar Roy, Forbes, June 19 2019 Original article published in Forbes. Why Digital Transformation Isn't Happening - - And How You Can Change ThatThis article written for Forbes by Bhaskar Roy, explains true problems that enterprises face when attempting to successfully digitally transform themselves, and potential ways of solving these. However, we think it can be taken further. What do 'technology investments with the future in mind' look like and how can these solve enterprises' digital transformation problems?

Roy makes excellent points about why businesses are failing to digitally transform themselves, however some of these need to be explored further. Yes, it is easy to underestimate 'the damage complex processes can do, both to your digital transformation goals and to overall productivity', but what if this complexity was removed? Part of the reason that enterprises are failing at successful digital transformation is the fact that on average, they are utilising '1,935 apps... a 15% increase compared to 2017'. The perception individuals have about digital transformation being down to them spending ridiculous amounts of money and adopting multiple different apps and technologies, is flawed, as Roy agrees. Exploring this further reveals the true issue with digital transformation, that by adhering to this mindset, companies are creating complexity for themselves, as their data is disparate and confined to a multitude of different apps and silos that are difficult to manage. The removal of this complexity with a single technological solution that collates all a company's data and allows it to intelligently communicate with each other, as well as one that enables information to be gathered and shared with external organisations, could be the answer. This would enable a business to utilise its data more effectively and being to digitally transform itself. While complexity is the main issue encountered by businesses, Roy suggests that a true solution to all business problems would be for companies to adopt 'a combination of business, process and technology', which to a certain extent is true, but is not an entire solution. A technological solution is still possible, while still accounting for the business and the process elements that are so important to a company's development. Technology that is centred around a users specific needs; one that is scalable and can be built around the business, could be the true answer. This keeps the business' main interests central, and also means technology can be adopted with process and future processes in mind, as it allows for any changes the company may encounter, whether these are developments or setbacks. According to Roy, 'even the best technology can't make up for complicated, difficult to execute processes', but we think it can. A single technological solution could be the answer to successful digital transformation; a virtual interoperable ecosystem with a future focus. An environment that is entirely secure, scalable, and able to be built around you and your company's specific needs. Discover more on our website. 'Human buy-in' needed for digital twin deploymentProfessional Engineering, Institution of Mechanical Engineers, July 2 2019 Originally Published by Professional Engineering in Institution of Mechanical Engineers Faced with increased competition in asset data management, Rolls-Royce Power Systems (RRPS) realised that it needed to change the way its client base was served. It appeared that what was needed was a technology solution, in the form of a virtual representation of physical systems. But, the outcome also called for a complete strategic rethink at management level.

"The issue was that we didn't see our products the way our customers do," says Sean Gigremosa. "We saw data that was stored in different systems and our focus was on those silos. We saw the world based on our technology and process, infrastructure and delivery methodology." The conceptual shift put in place by RRPS was to put "what matters to customers at the centre of what we do". Practically, this meant the installation of asset-focused digital twins providing a single access point for the data needed by service managers to resolve customer service issues and deliver systems insights. To do this, RRPS harnessed digital twin technology from Iotic, to provide a virtual composite of the entirety of an asset's data and controls, "securely and meaningfully, while interacting with other twins, to provide a single source of truth that helps suppliers become service providers and customers to become partners". This benefits the client in three ways. First, potential problems can be identified more promptly, leading to faster issue resolution. The second is quality, with Gigremosa explaining that the implementation of digital twins, "means that we see not only each customer's point of view, but can collectively gain insight across a customers assets enabling us to improve our products". Third is the provision of detailed insight to the customer, which can anticipate problems before they arise, with the result that there is reduced downtime. For all the technology, to achieve these goals there needed to be human buy-in. Gigremosa says that if he could pick one word to define how success was achieved, it is involvement. "Agile development focuses on the user, so we started with our service management personnel, involving the team, testing and validating at every stage," he says. "We ran a design thinking process to understand our customer needs, Ultimately, agility depends on people. Being agile has put the customer at the heart of our everyday conversations." Which is more than simply predicting their requirements: "It's really about including the customer in the discussion, so they can tell you what they want." This is where Gigremosa points out that it's important to draw distinctions between business, digital and process transformations. While business transformation is a common goal, and digital transformation - in this case, the implementation of digital twins - is what needs to be done to achieve this, it is the area of process transformation that can create roadblocks, because "you're asking users to do new things in new ways, and disrupting downstream services. Key to the RRPS implementation of Iotic is that the process is "additive and complementary to existing workflows". The user experience is enhanced in such a way that disruption is kept to a minimum, making acceptance of, and involvement in, the new landscape "easier for everyone". "The main driver for change is the environment we find ourselves in," says Gigremosa. Because technology is moving "so fast, start-ups and more agile companies are now able to compete with larger organisations. Think about Amazon," he says, "that was at first only an online bookseller. But, due to agility and innovation, it has become one of the largest and most successful companies in the world." Learning Camera project is developing AI - enabled tech to boost UK construction industry productivityCranfield University, 26th June 2019 Originally Published by Cranfield University. Researchers from Cranfield University are working with BAM Nuttall and Iotic, to develop an artificial intelligence-enabled safety board monitoring system for the UK construction industry. Funded by Innovate UK, The Learning Camera project aims to improve safety, while reducing the number of health and safety-related tasks carried out by construction staff, in order to improve productivity.

The project is using a combination of technology concepts including the Internet of Things, computer vision, Semantic Web, machine learning and cloud technologies, to develop self-learning technology capable of monitoring and analysing various scenarios on construction sites. The UK construction industry is said to have poor productivity in comparison to other sectors - in part due to ever-changing project environments and large amounts of regulation when it comes to health, safety and environmental issues. While this highly-regulated approach is currently wholly necessary, it is hoped that the new technology will reduce the burden on staff - in terms of both tasks and resources - meaning more of their time can be spent on tasks directly impacting the build, therefore increasing productivity while maintaining the same level of safety standards, The Learning Camera project will focus on developing a safety board monitoring system, which automatically alerts staff if any safety equipment is used or missing. Dr Yifan Zhao, Lecturer in Image and Signal Processing and Degradation Assessment at the Through-life Engineering Service Institute at Cranfield University, believes this is a great opportunity to apply artificial intelligence technologies to a traditional industry. Dr Zhao said: "Using The Learning Camera, construction sites will be better equipped to manage and deliver projects. It also helps to promote the need for the construction industry to attract talent with skills in software and hardware development, in order to tackle the much-publicised poor productivity of the industry." Colin Evison, Head of Innovation at BAM Nuttall, said: "This is a real opportunity to explore how we can make our construction projects smarter by the adoption and development of technology solutions that are not traditionally available in the construction industry. The use of tools such as The Learning Camera will enable out people to focus more of their efforts on the actual delivery of projects, with the knowledge that it will notify them automatically if their intervention is required. In addition, by creating new additive business relationships with organisations such as Iotic Labs Limited and Cranfield University, we are able to have access to talent and resources in different sectors." Sophie Peachey, Head of Customer Success at Iotic, said: "The application of Digital Twin technology within The Learning Camera allows us to broker access to a potentially increasing number of data sources and controls to perfect the accuracy of the algorithms used in solution. these algorithms must be able to interpret differences correctly and instigate appropriate actions to make The Learning Camera a solution that people trust. You can see how this could apply to different situations in which people have to balance the importance of knowing that something is there, has changed, or is working, against the cost of their time in checking. While this is not restricted to construction, we are very excited by the impact this could have on productivity and in providing construction staff with a safe working environment. Find out more about The Learning Camera project. |

AuthorS

Ali Nicholl Archives

November 2019

Categories |

Iotic Office North America

|

|

RSS Feed

RSS Feed